IEC 62619: Complete Battery Pack Safety Certification Overview (Part 2)

Why Perform IEC 62619 Testing?

IEC 62619 requires both cells and battery systems to undergo a series of safety verifications, ensuring that under normal operation and “reasonably foreseeable misuse”, no fire or explosion will occur.

The testing is divided into two parts:

- Cell-level testing: Verifies the safety of individual cells.

- Battery system-level testing: Verifies the protection capability of the Battery Management System (BMS) and the entire battery pack under abnormal conditions.

For a more detailed explanation, see this article: IEC-62619 Cell-Level Certification vs Battery Pack Certification (Part 1)

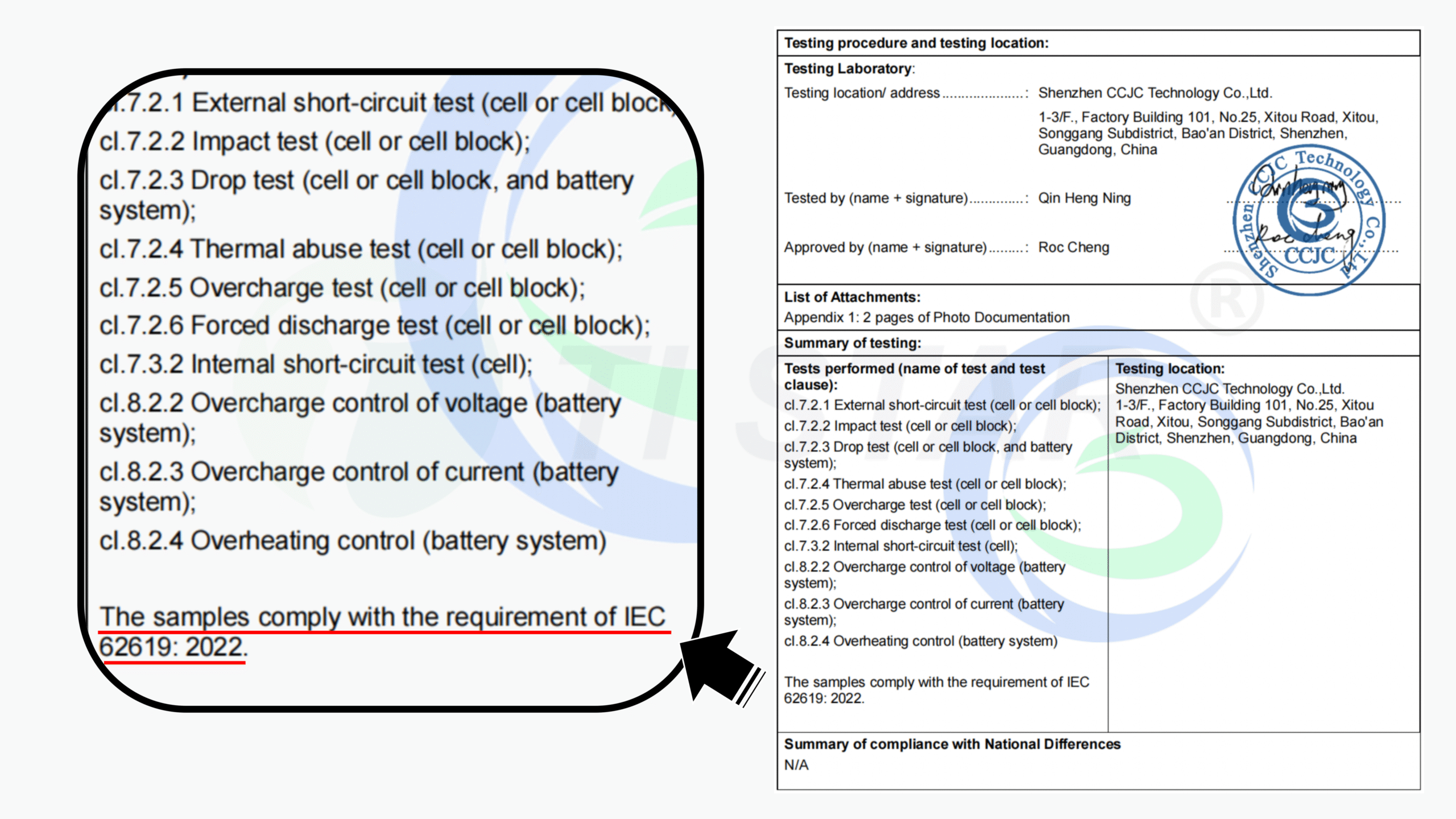

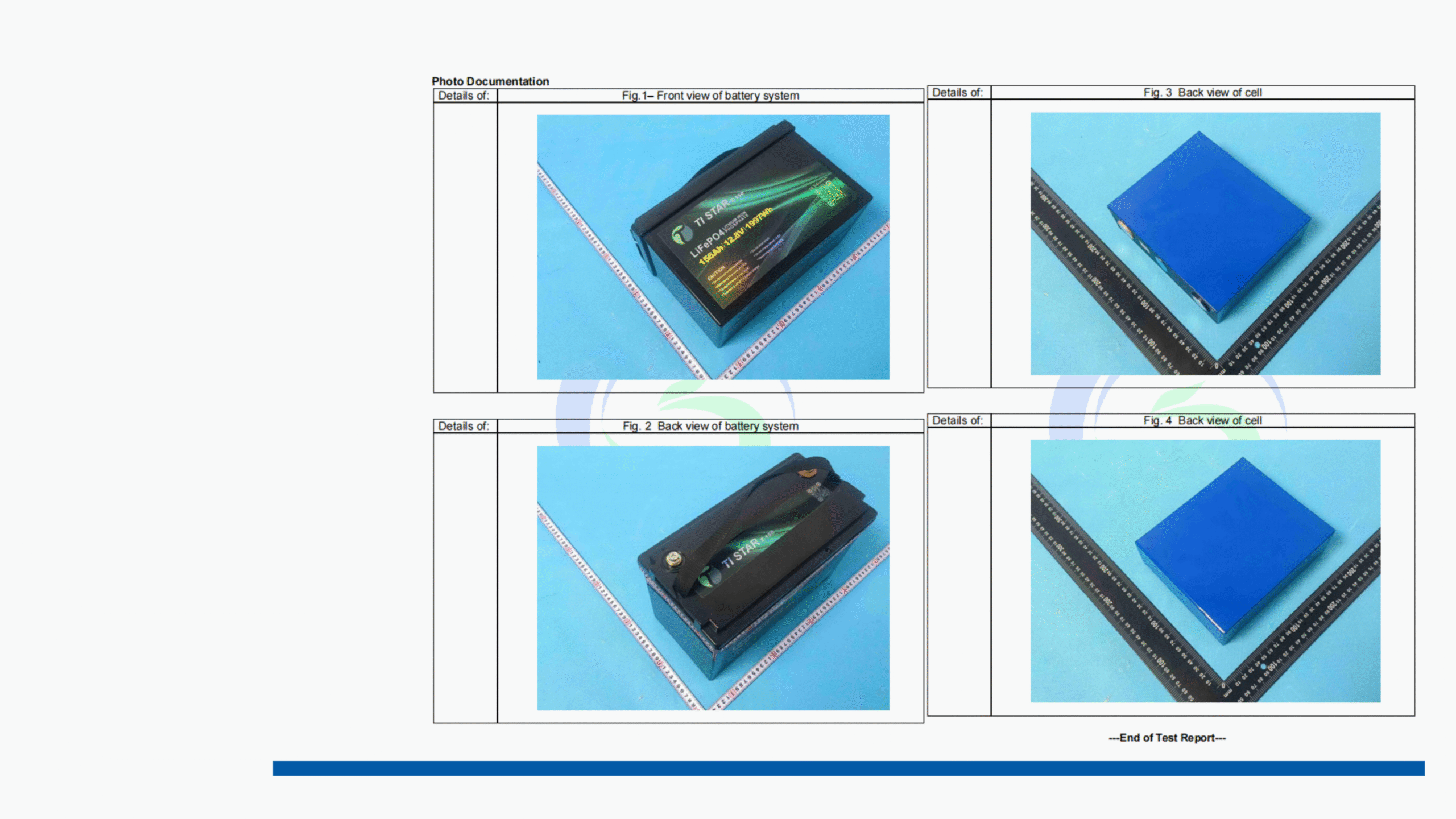

Cell-Level Test Results

(Test results based on sample model T150)

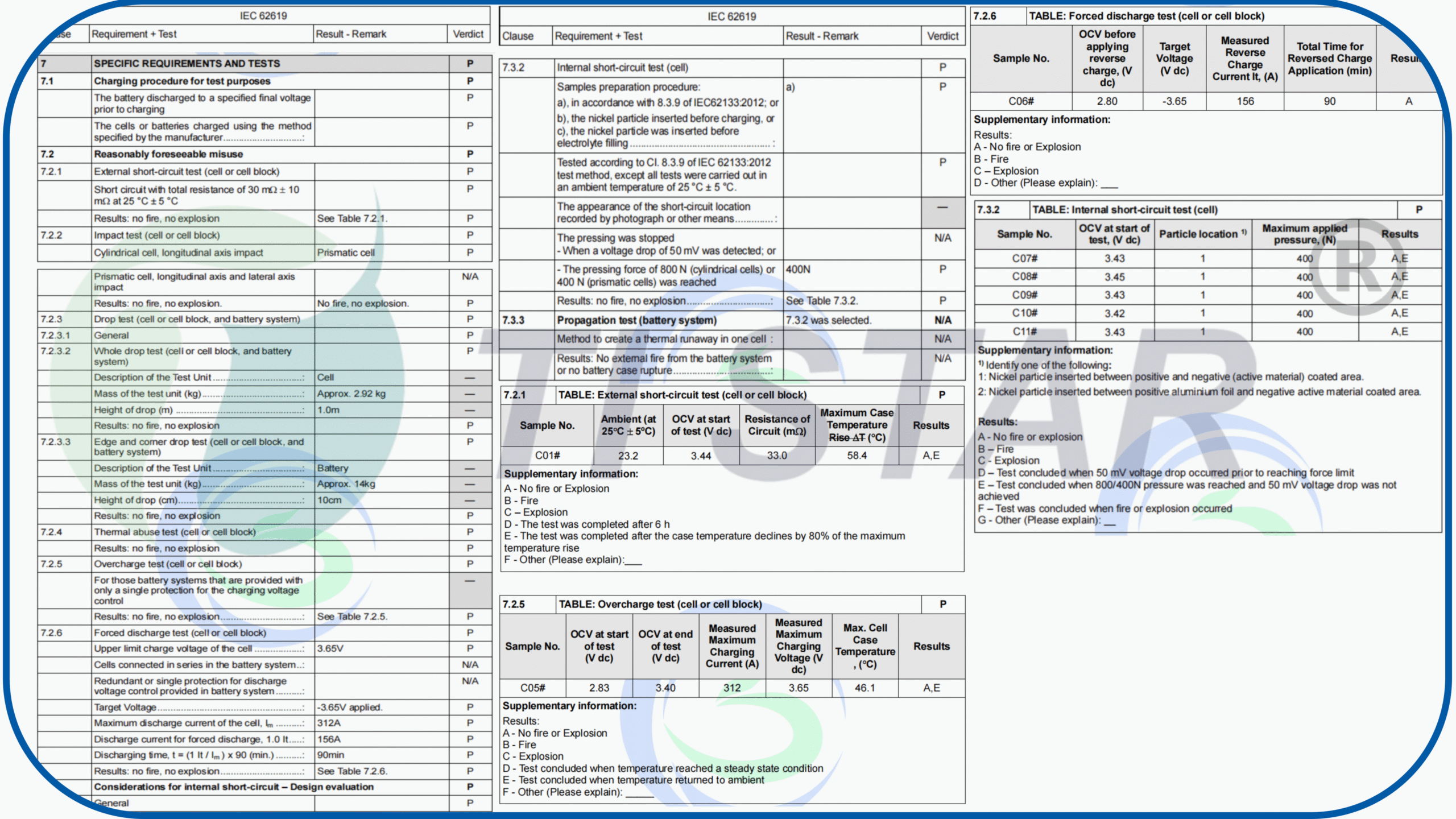

Cell-level tests focus on short circuit, mechanical impact, drop, thermal abuse, overcharge, forced discharge, and internal short circuit.

- External Short Circuit (7.2.1): At 25°C, the cell was short-circuited with a 30 mΩ resistor. Maximum temperature rise: 58.4°C.

✅ Result: No fire, no explosion. - Impact Test (7.2.2): Simulated impact during transportation or use.

✅ Result: No fire, no explosion. - Drop Test (7.2.3.2): An approx. 2.92 kg cell dropped freely from 1.0 m.

✅ Result: No fire, no explosion. - Thermal Abuse (7.2.4): Forced overheating (temperature not specified).

✅ Result: No fire, no explosion. - Overcharge (7.2.5): Charged at 312 A up to 3.65 V; max temperature 46.1°C.

✅ Result: No fire, no explosion. - Forced Discharge (7.2.6): Reverse voltage 3.65 V, 156 A, 90 min.

✅ Result: No fire, no explosion. - Internal Short Circuit (7.3.2): Nickel particles inside, 400 N pressure.

✅ Result: No fire, no explosion.

Conclusion: Cells remained stable under all extreme conditions, with no hazardous failures.

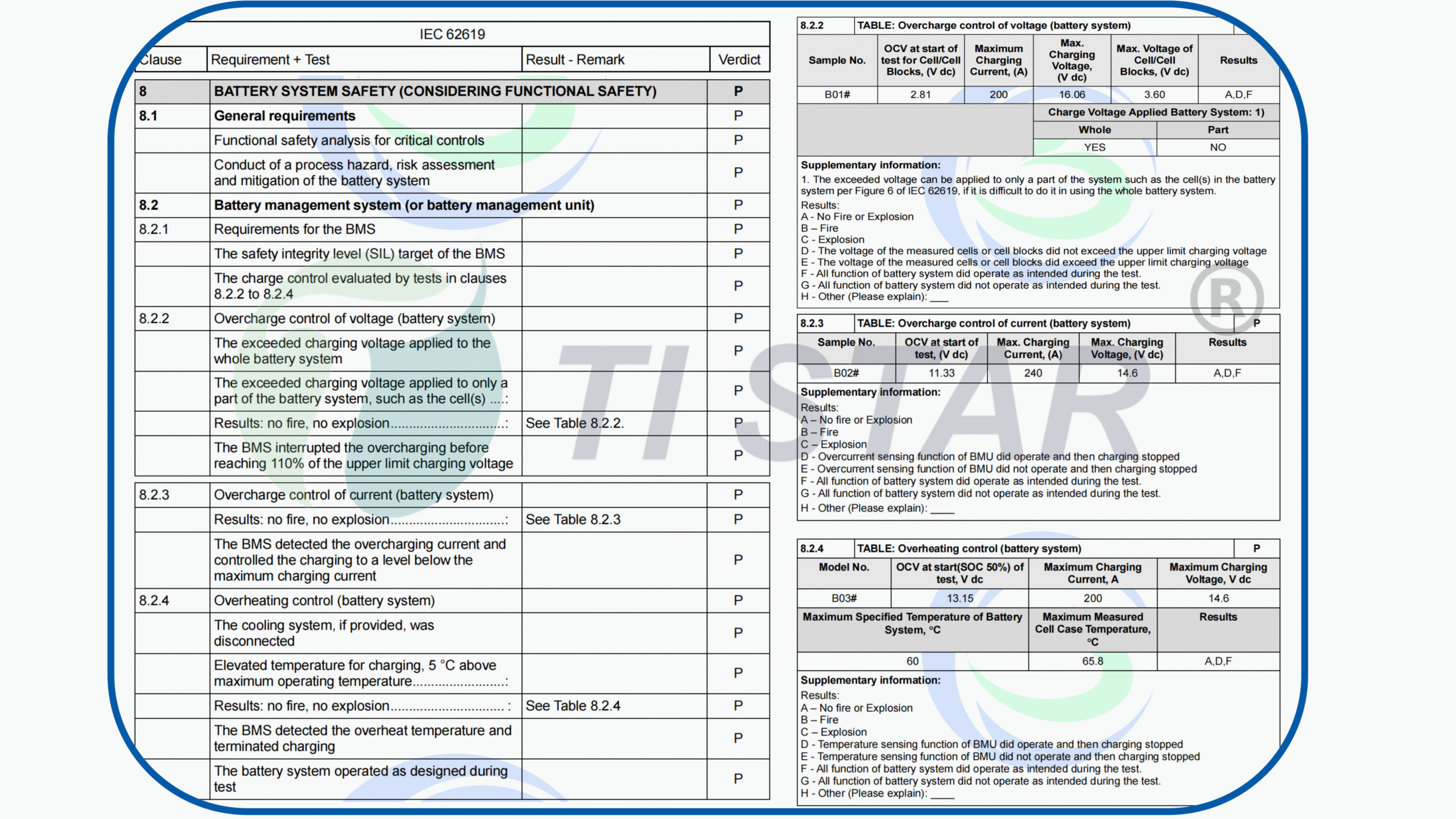

Battery System-Level Test Results

(Test results based on sample model T150)

System-level tests focus on the protection capabilities of the entire pack and its BMS. Key items include drop, over-voltage protection, over-current protection, and overheating protection.

- Edge/Corner Drop (7.2.3.3): 14 kg battery pack dropped from 10 cm.

✅ Result: No fire, no explosion. - Over-Voltage Protection (8.2.2): Pack subjected to 16.06 V (cell voltage 3.60 V). BMS cut off charging before exceeding limits.

✅ Result: No fire, no explosion. BMS functioned properly. - Over-Current Protection (8.2.3): Excessive charging current 240 A. BMS detected and stopped charging.

✅ Result: No fire, no explosion. System operated normally. - Overheating Protection (8.2.4): Ambient temperature raised 5°C above rated limit (up to 65.8°C). BMS terminated charging.

✅ Result: No fire, no explosion. Function operated correctly.

Conclusion: The BMS provided timely protection against over-voltage, over-current, and overheating, demonstrating a solid safety design.

Summary

- Cell Tests: External short circuit, drop, overcharge, forced discharge, and internal short circuit all passed with no fire or explosion.

- Battery System Tests: The BMS responded effectively to abnormal voltage, current, and temperature conditions, avoiding risks.

- Compliance: Overall results fully meet the safety requirements of IEC 62619:2022.

This report confirms that the tested cells and battery system are safe and reliable. Even under harsh conditions, they remained stable, meeting international standards for industrial lithium battery safety.

Summary: These cells and battery systems have passed the full IEC 62619 safety test suite. In extreme cases such as short circuit, overcharge, drop, and high temperature, they posed no danger—proving their design is safe and reliable.