“I can buy the same capacity battery at a lower price.”

Why Are Our Batteries More Expensive?

A question we often hear from customers is:

“Why are your batteries more expensive than others? I can buy the same capacity battery at a lower price.”

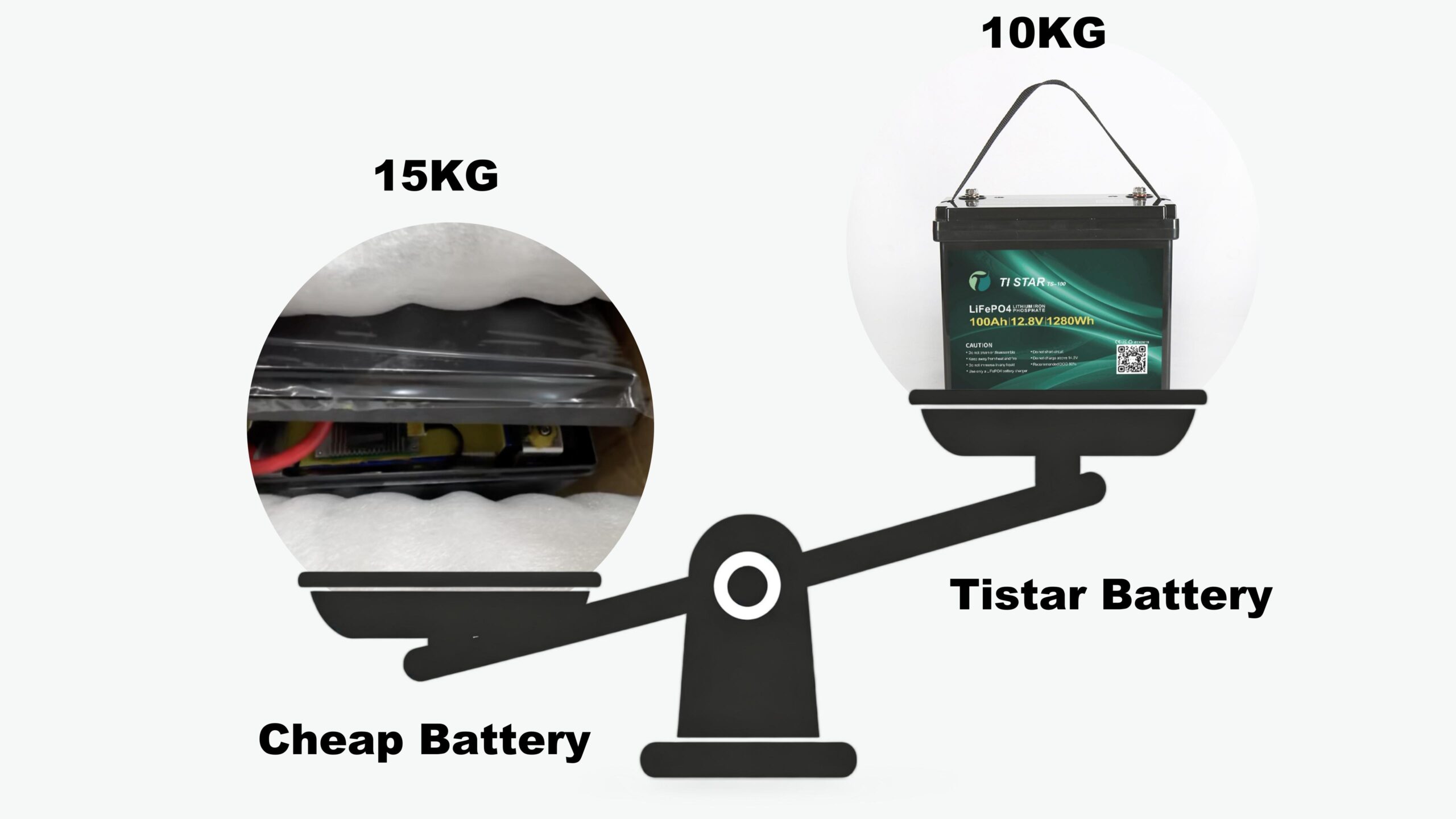

To address this concern, we disassembled a 12.8V 100Ah battery sold for just over A$ 200 .

By examining its internal structure and workmanship, several key differences became clear:

1. Cell Quality Differences

One major reason low-cost batteries often appear heavier despite the same rated capacity comes down to the cells used. There are typically two possibilities:

Lower energy-density cells

These cells store less energy per kilogram. As a result, even when the label claims the same 100Ah capacity, the actual weight can be much higher. The unit we opened weighed 15kg, whereas our T100 (12.8V 100Ah) weighs only around 10kg. This weight gap highlights significant differences in energy density and also points to poorer performance in cycle life and endurance over time.

Use of B-grade cells

B-grade cells are those that fail to meet A-grade standards during factory testing, often due to inconsistent capacity, higher internal resistance, or poor uniformity. To mask these shortcomings, some manufacturers may use larger nominal cells (for example, 120Ah cells) to assemble a “100Ah” battery. While it may appear sufficient in the short term, such batteries typically degrade faster, run hotter, and deliver a much shorter service life.

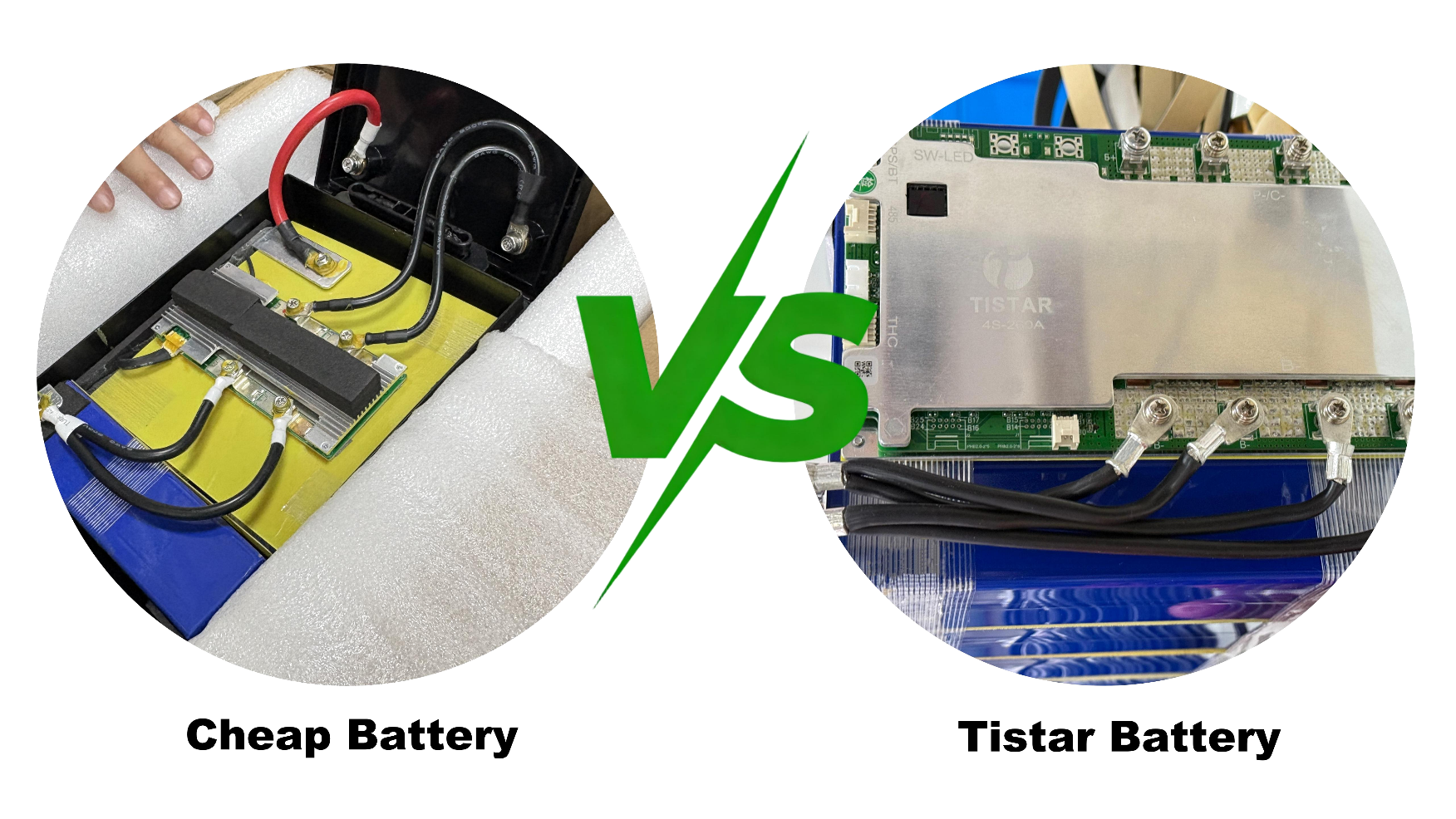

2. Inadequate BMS Design

The battery management systems (BMS) in low-cost units are often extremely thin, with undersized aluminum heat sinks.

Poor thermal management increases the risk of overheating during prolonged use, leading to capacity loss, shortened lifespan,

or even severe safety hazards such as thermal runaway or fire.

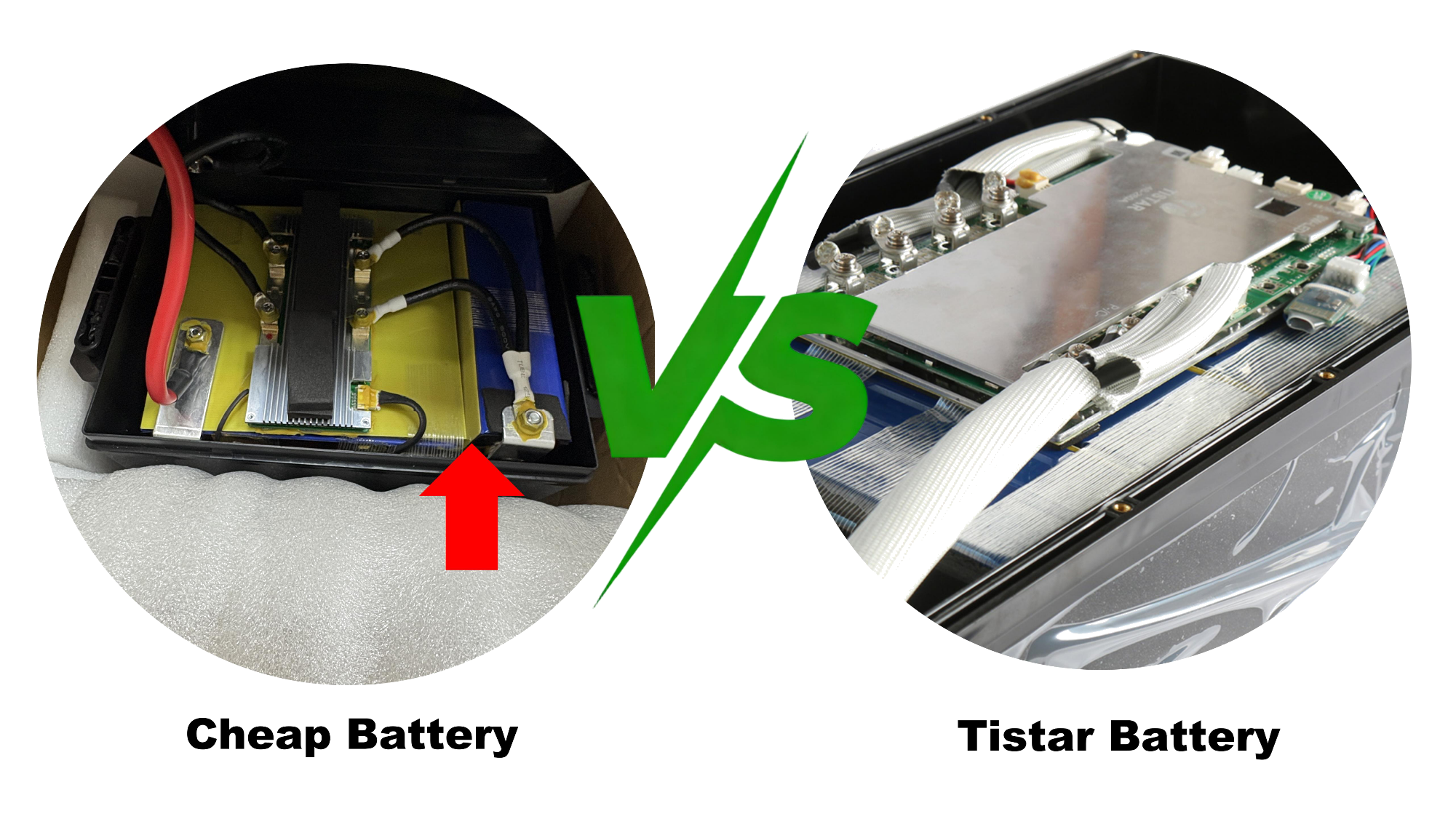

3. Rough Workmanship and Poor Cell Arrangement

Cheaper batteries tend to cut corners in assembly. Cells may be placed haphazardly without proper design considerations,

which results in imbalanced charging and discharging. Some cells end up overcharged or over-discharged,

accelerating degradation and reducing the overall reliability of the pack.

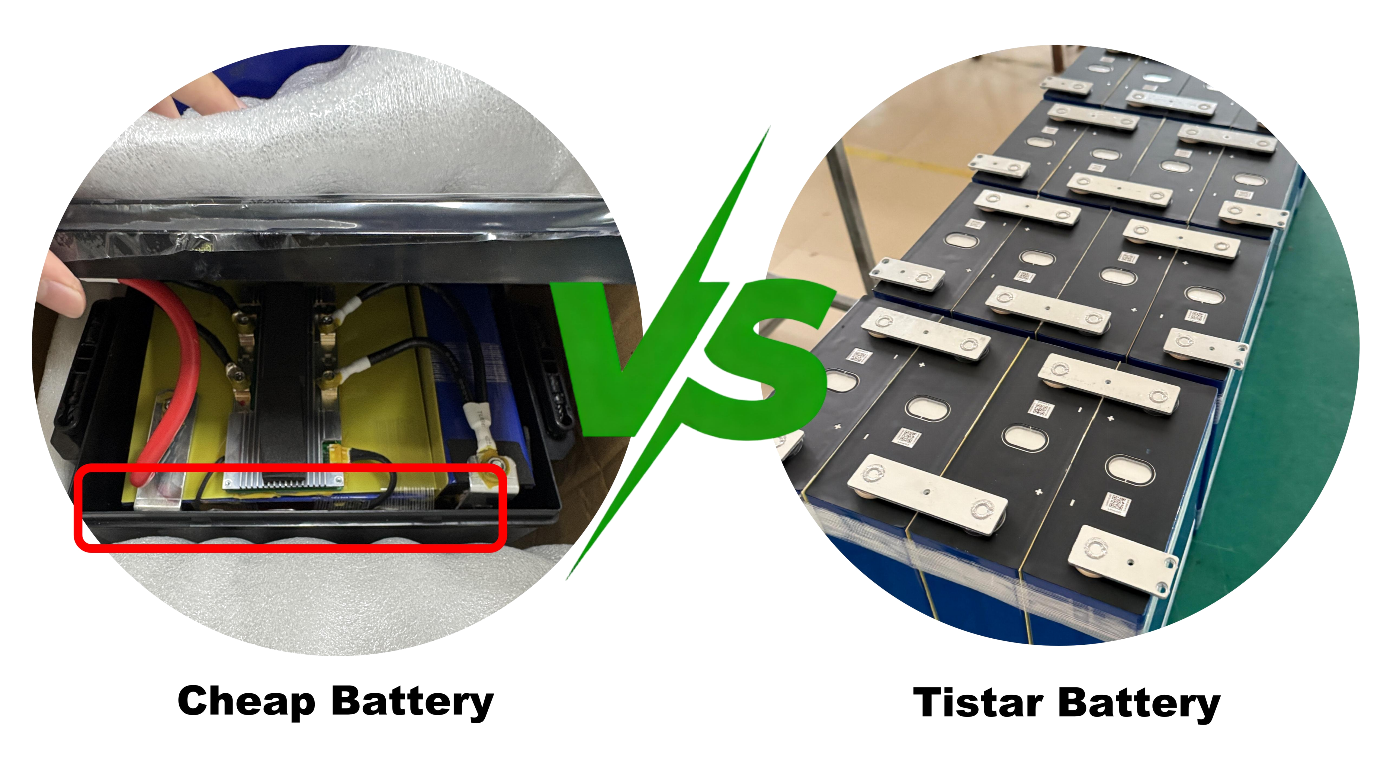

4. Epoxy Board Quality Issues

In low-cost batteries, epoxy boards are often cut manually, leaving uneven and rough edges.

Such imperfections compromise the pack’s structural stability and may increase the risk of internal damage or short circuits over time.

By contrast, our batteries use epoxy boards cut by precision machinery, ensuring clean, uniform edges and a smooth finish.

This not only improves structural integrity but also enhances safety and long-term reliability.

In Summary

While cheaper batteries with the same rated capacity do exist, the trade-offs in

cell quality, BMS design, workmanship, and structural safety are significant.

These compromises result in shorter lifespan, lower performance, and higher safety risks.

Our batteries are built with high-grade cells, robust designs, and rigorous quality standards—ensuring consistent performance,

long service life, and most importantly, safety. This commitment to quality is the fundamental reason why our products cost more.